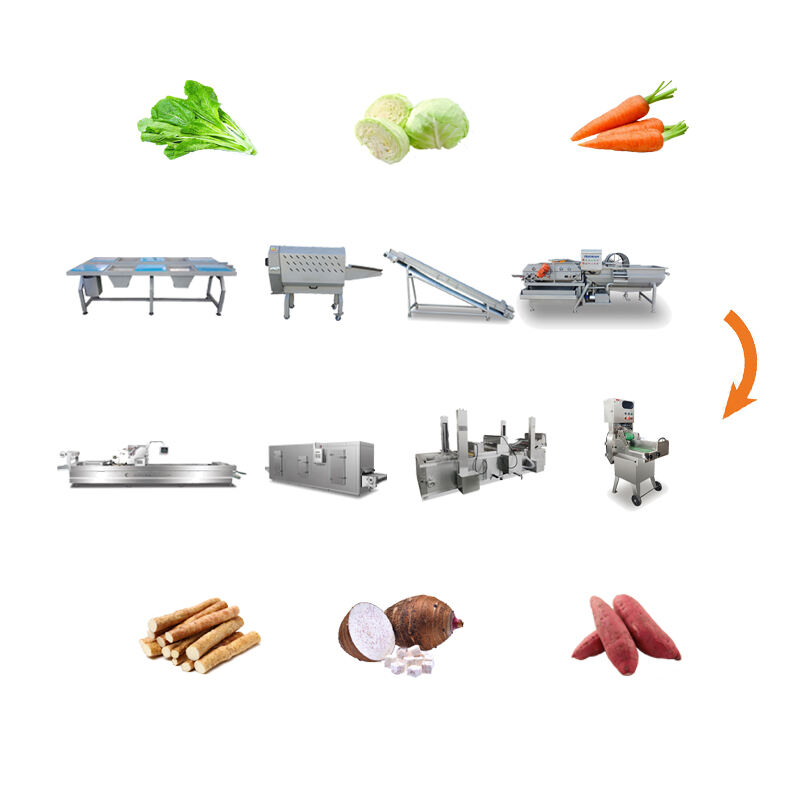

Mild, men likevel effektiv rensing for ulik produksjon.

I vår bedrift sørger vi for at vårt utstyr for vasking av frukt og grønnsaker har høytrykksvannstråler, sammen med lett børstevasket skjørt rengjøring, eller luftboblevask, for å forhindre skade på følsom produksjon mens vi fjerner jord, pesticider og annet affall. Våre vasketunneler og konveyorbånd som kjører på justerbare farten fra 0,5 til 5 meter per minutt dekker en rekke av økter, fra følsome bær til tøffe rotgrønnsaker. For eksempel, poteter vaskes med stubbet jord ved hjelp av en to-trinns børste- og vannvask, mens bladgrønnsaker, som spinat, vaskes med skjørt luftbobler for å forhindre slitasje. Den modulære designen sikrer optimal renset for mer enn et hundredtall frukt og grønnsaker ved å gjøre det mulig å raskt bytte mellom ulike typer produksjon.