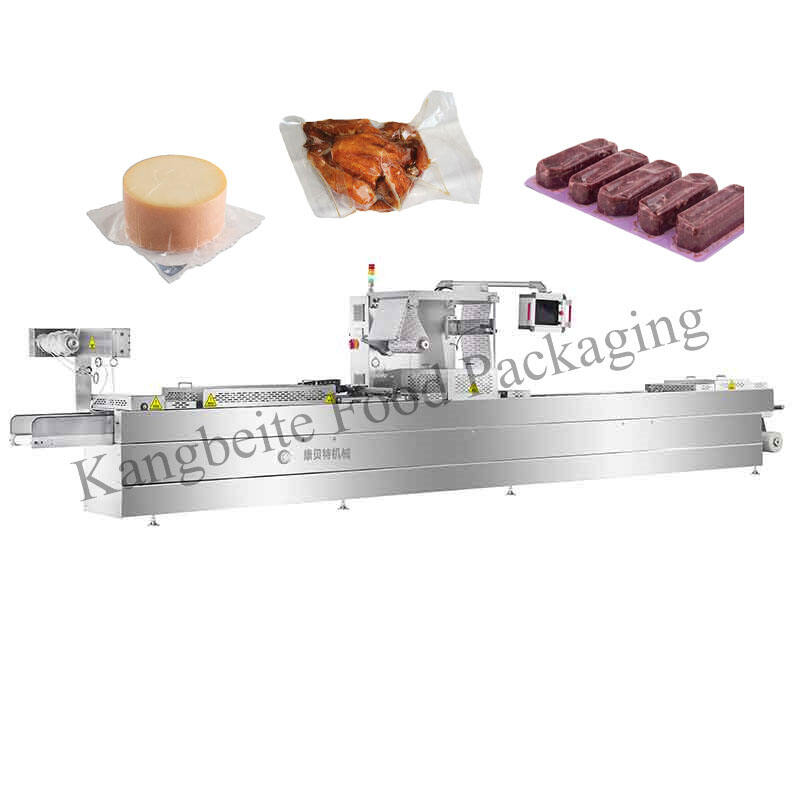

A high speed thermoforming packer is an automated packaging system designed for high-volume production, capable of forming, filling, and sealing packages at rates of 60–120 packages per minute (CPM)—far exceeding the speed of semi-automatic models—making it ideal for industries like food, pharmaceuticals, and consumer goods where large-scale packaging is critical. Its core advantage lies in a continuous, integrated workflow that minimizes downtime: the machine unwinds a roll of thermoplastic film (e.g., PET, PP, PVC, or multi-layer laminates) into a heating station, where the film is softened (at 90℃–150℃, depending on film material) and formed into a tray or pouch via vacuum or pressure. The formed film then moves to a filling station, where automated feeders dispense products (solids, liquids, powders, or delicate items like candies) with high precision—volumetric fillers for liquids/powders, weigh fillers for solids, or pick-and-place robots for irregularly shaped items. After filling, a top film (either pre-printed or plain) is unwound and sealed to the base film via heat and pressure, with optional gas flushing (for MAP) or vacuum sealing (for oxygen-sensitive products) integrated between filling and sealing. The final station trims excess film, separates individual packages, and discharges them onto a conveyor for downstream processes (labeling, cartoning). To maintain speed without sacrificing quality, high speed thermoforming packers use advanced technologies: servo motors for precise film tension control (preventing misalignment), PLC-based control systems with touchscreen HMIs (for quick recipe changes and real-time monitoring), and inline sensors (to detect missing products, seal defects, or film breaks, triggering automatic adjustments or shutdowns). Film compatibility is broad—they handle thin films (15–30 μm) for lightweight packages and thick films (50–100 μm) for heavy or puncture-prone products, with optional die changes (in 30–60 minutes) to switch package sizes/shapes. Energy efficiency is optimized via zone heating (only heating the film area needed for forming) and heat recovery systems. Compliance with global standards includes FDA-approved food-contact materials, CE marking for safety (EU), and UL certification (North America). For manufacturers, this packer reduces labor costs (1–2 operators vs. 5–6 for manual lines), ensures consistent package quality (seal strength, fill accuracy), and scales to meet peak demand (e.g., holiday seasons for food products). It is widely used in packaging snacks, frozen foods, pharmaceuticals, and personal care items, enabling brands to supply large retail chains and global markets efficiently.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy